Consumer packaged goods companies need solutions that protect their products from the rigors of shipping and handling, align with their brand values and meet growing consumer demand for sustainability. Wise decision-making involves balancing strength, cost and environmental impact.

This guide defines corrugated boxes and examines the strengths and sustainability profiles of frequently used materials to help you make an informed choice for your business.

What Is Corrugated Packaging?

Unlike flat cardboard, corrugated packaging is a paragon of strength and durability. Its unique structure makes it lightweight, resilient and essential in shipping and packaging.

Corrugated Board Structure

Corrugated boxes consist of three layers working together. The two outer layers, called linerboard, provide a smooth, durable surface for high-quality printing and branding. Linerboard also protects the box from moisture and external elements.

Between the outer layers is the medium, a wavy, fluted paper sheet that imparts core strength. The fluted arches form air cushions that absorb shocks and give the cardboard structural integrity and crush resistance.

A starch-based adhesive holds the corrugated packaging structure together. This bonding agent is nontoxic, food-safe and derived from a renewable resource, making it an eco-friendly choice.

Flute Sizes

“Flute” refers to the size and shape of the waves in the medium. Different flute profiles provide various benefits, and you can combine them to get your desired properties.

- A-Flute (33 flutes per linear foot): Offers extra cushioning for fragile items needing shock absorption during shipping.

- B-Flute (47 flutes/foot): Balances crush resistance and printability, often used for canned goods and retail displays.

- C-Flute (39 flutes/foot): The most common profile, offering a mix of durability and cushioning for standard shipping boxes.

- E-Flute (90 flutes/foot): Thinner with less cushioning, but ideal for high-quality printing.

- F-Flute (125 flutes/foot): The narrowest, used for small, intricate cartons like those for cosmetics and jewelry.

Comparing Corrugated Strength to Other Materials

Choosing the ideal protection depends on your product, shipping environment and budget. How does corrugated board stack up against other packaging materials?

Corrugated Packaging

Its design provides strength and efficiency.

- High strength-to-weight ratio: Corrugated packaging products offer excellent protection without adding unnecessary weight, resulting in shipping cost savings.

- Superior crush resistance: The fluted medium makes corrugated board resistant to crushing, measured by the Edge Crush Test.

- Customizable protection: It can be custom-designed with internal dividers and pads to create a solution that protects products of any shape or size.

Plastic

Often chosen for its durability, plastic has distinct strengths and weaknesses.

- Moisture resistance: It offers a barrier against liquids and humidity, making it suitable for specific food and beverage products.

- Potential for cracking: Rigid plastics can become brittle and crack in cold temperatures, while flexible plastics offer little to no protection against impact or crushing.

- Versatility in form: It’s possible to mold plastic into nearly any shape, from rigid containers to flexible pouches and films. This flexibility makes plastic suitable as primary packaging.

Glass

Valued for its premium look and feel, glass is a popular choice for luxury goods. However, strength is not its primary feature.

- Rigidity and perceived quality: It conveys a sense of high quality but is inherently fragile.

- Weight and fragility: Its weight raises shipping costs, and its fragility often requires additional corrugated packaging to prevent breakage.

- Product purity and barrier quality: Glass does not interact with contents, forming a perfect barrier against contaminants and making it ideal for preserving food, beverages and pharmaceuticals.

Wood

Wood is traditional for heavy-duty applications.

- Exceptional strength: Wooden crates offer high levels of protection for heavy, bulky or high-value industrial goods.

- Weight, cost and practicality: Wood is heavy, expensive and prone to splintering. It is an impractical and costly solution for most CPG products.

- Superior stacking strength: Wood’s rigidity provides excellent stacking strength, maximizing warehouse and transport space.

Metal

Metal is the most durable packaging material, used in specialized cases.

- Maximum durability: Metal containers offer unparalleled protection and security.

- Prohibitive cost and weight: The expense and heft make it impractical for most consumer products.

- Complete barrier protection: Metal is imperious to light, water and oxygen, protecting contents from degradation over time.

Comparing the Sustainability of Packaging Materials

Sustainability is now a business priority driven by three primary forces:

- Stricter regulations have made compliance essential.

- Customers prefer brands that demonstrate environmental responsibility.

- We have an ethical duty to protect the planet for future generations.

Here is a comparative look at the sustainability of corrugated packaging versus other materials.

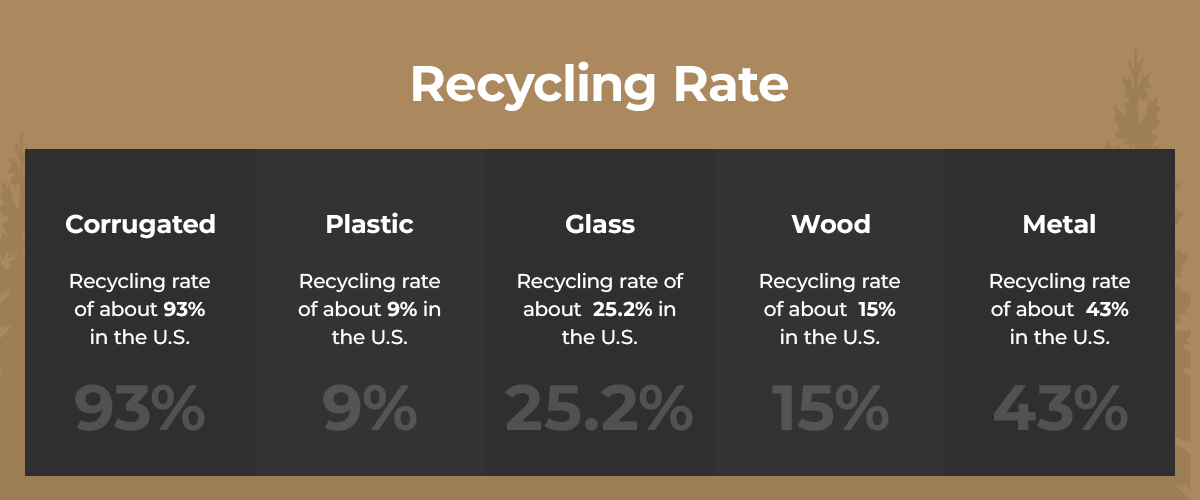

Recycling Rate

Recycling rate is a crucial measure of a material’s role in the circular economy. Here’s how packaging materials stack up.

- Corrugated: An impressive recycling rate of about 93% in the U.S. The fibers are fully reusable to create new paper-based products.

- Plastic: A low recycling rate of about 9% for post-consumer plastic waste. Most plastic packaging ends up in landfills, incinerators or in the environment.

- Glass: While 100% recyclable, the recycling rate for glass containers in the U.S. is around 25.2%. The process is energy-intensive compared to other materials.

- Wood: Wood packaging, like pallets and crates, has a recycling rate of approximately 15% in the U.S. It typically gets chipped and repurposed as mulch or biomass fuel.

- Metal: Has a robust recycling profile, especially for aluminum cans, which have a U.S. recycling rate of about 43%.

Biodegradability

This criterion evaluates whether materials break down or persist in the environment for extended periods.

- Corrugated: Fully biodegradable. If cardboard ends up in a natural environment, it doesn’t take long to break down.

- Plastic: Not biodegradable. Plastic breaks down into microplastics over centuries, contaminating ecosystems.

- Glass: Not biodegradable. However, it is chemically inert, so it does not degrade or release harmful chemicals into the soil or water.

- Wood: Fully biodegradable, decomposing naturally and returning its nutrients to the soil, just as a fallen tree would in a forest.

- Metal: Not biodegradable. It will rust and break down over a very long period, returning its mineral elements to the earth without releasing toxins.

Renewable Source

A material’s sustainability depends on whether it comes from renewable or finite resources. These common packaging materials derive from several sources.

- Corrugated: Corrugated packaging products are a highly sustainable, renewable choice when sourced from responsibly managed forests, certified by organizations like the Forest Stewardship Council.

- Plastic: Derived from nonrenewable fossil fuels like petroleum and natural gas. Making plastic involves extracting and consuming finite resources.

- Glass: Made from abundant but nonrenewable sand, soda ash and limestone, which take thousands of years to form.

- Wood: Wood is a classic example of a renewable resource. It’s possible to harvest trees sustainably and plant new ones to ensure a continuous supply.

- Metal: Produced from mined ores, which are finite, nonrenewable resources. Initial mining and processing have a significant environmental impact.

Selecting Your Products Wisely

Understanding each material’s strength and sustainability helps you pick the best option for your business. The best choice depends on your product requirements.

Consider if your items need robust cushioning against impact, insulation for temperature control or a reliable moisture barrier. Corrugated products have unique properties and are customizable to meet a wide range of protective needs.

Also, consider the entire supply chain. Stackable packaging with a high strength-to-weight ratio optimizes logistics and reduces costs.

Your packaging should reflect your brand identity. Eco-friendly packaging shows your commitment to sustainability and strengthens your reputation.

Partner With Great Northern for Strong, Sustainable Packaging

When you work with an expert partner, you won’t have to sacrifice any of your business goals to get high-quality consumer packaging solutions. Great Northern Packaging delivers innovative, cost‑effective custom corrugated designs that pair durability and sustainability.

Our award-winning design and engineering teams create packaging to safeguard your products, streamline your supply chain and elevate your brand image.

Are you ready to impress your customers and take your business to the next level? Contact us today to explore custom corrugated options.