- Reduced item count and carton consolidation

- Optimized product performance

- Reduced BER content and improved packaging sustainability scorecard

- Improved pallet pattern for trailer and warehousing maximization

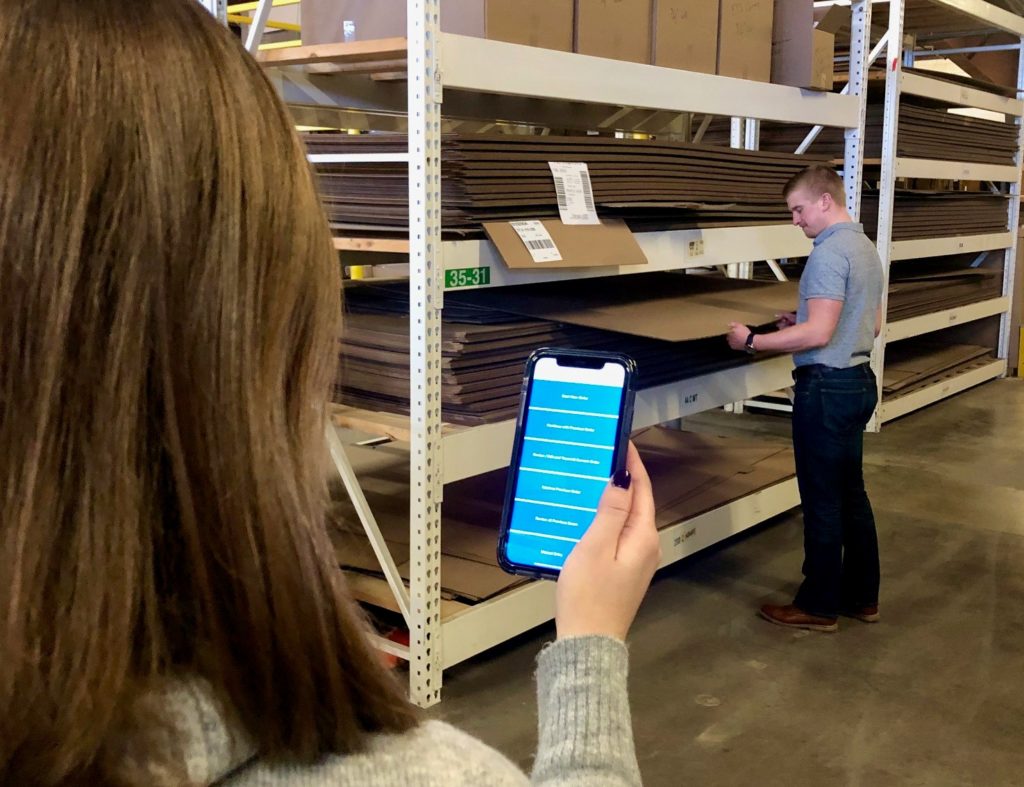

- Improve process flow and reduce labor

Course of Action | Results | Requirements |

|---|---|---|

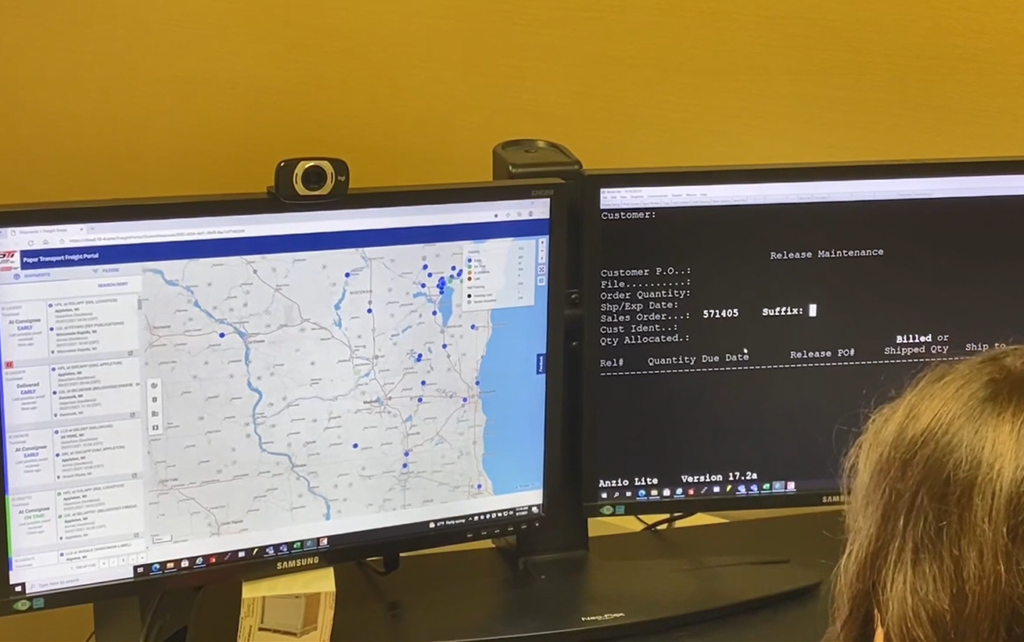

| Order Quantity Review | ||

| Delivery/Inventory | ||

| Transactions and EDI Options |