Corrugated packaging is a layered material that creates affordable, lightweight, strong and eco-friendly packaging solutions. It’s highly customizable, providing different types, styles and sizes of packaging to facilitate the shipping of various products. Corrugated packaging is actually the most commonly used material for packaging and transportation in North America.

Understanding Corrugated Packaging

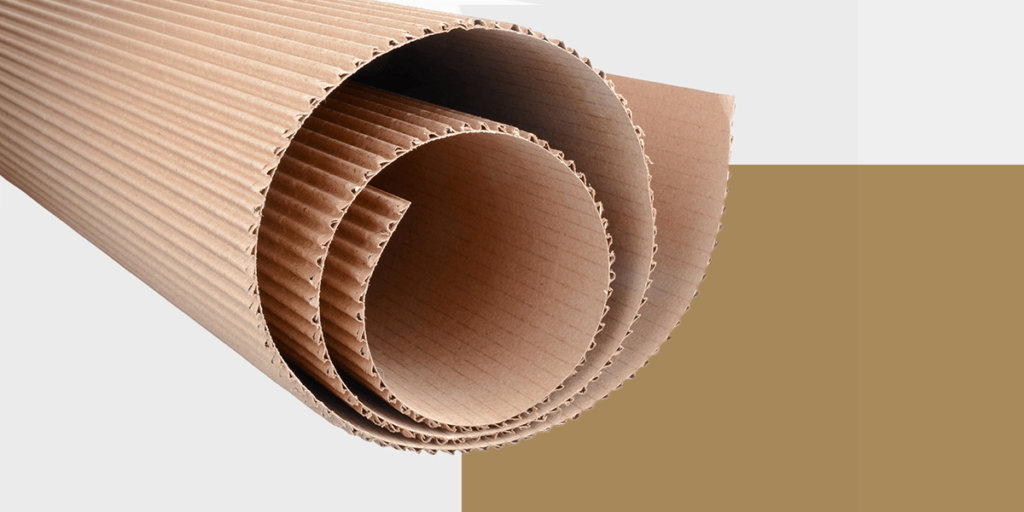

Corrugated packaging is made by gluing fluted paperboard sheets — the medium — between two sheets of flat liner board — the liner. It uses fluting to create strong structures that resist bending and pressure from all directions, which is ideal for shipping and distributing products. The distinctive layers of corrugated packaging also improve its structure and stability.

Kraft and test paper are the two most common materials used to create corrugated packaging. Kraft paper is often used for exterior liners because it has a smoother texture owing to its 70%-80% virgin chemical pulp fiber composition. This construction makes it easier to print on the corrugated packaging. It effectively protects the contents because it’s more water-, rip- and burst-resistant.

Test paper is an affordable alternative to kraft paper. However, it is more difficult to print on and less durable due to its higher recycled fiber content. It’s used for the inner liner of corrugated packaging.

Fluting is the middle layer of the corrugated packaging made from kraft paper. It’s bent to create C-shaped curls or waves glued to the liners. The size of the flutes determines the thickness of your corrugated box wall and the stacking strength.

Flute Sizes and Characteristics

The flute size is determined by the size of the arch and the number of flutes per given foot. The designations of corrugated packaging’s flute sizes include:

- A-flute: Considered the original flute profile, A-flute is ¼ inches thick or 33 flutes per linear foot. It provides ample protection for fragile items thanks to its thickness.

- B-flute: B-flute is 1/8 inches thick and 47 flutes per foot, making it perfect for storing and shipping canned goods and creating counter displays.

- C-flute: C-flute is 3/16 inches and can fit 39 flutes per linear foot. It is most commonly used for shipping boxes.

- E-flute: E-flute is about 1/16 inches and provides 90 flutes per foot. It has an extremely thin profile and lacks the structural strength of the thicker profiles. It’s often used as an alternative to paperboard packaging.

- F-flute: This is the narrowest flute profile (1/32 inches), and it fits about 125 flutes per linear foot. It’s best for creating small folding cartons.

Types of Corrugated Packaging

Corrugated packaging types can be categorized by wall thickness, which affects the packaging’s structural design, level of protection and design. The main types of corrugated packaging include:

- Single-face: Single-face combines layers of paper, including an outer layer and the fluting. It’s supplied in rolls cut to size and used to separate and protect individual fragile products, like glass and electronics.

- Single-wall: This type of corrugated packaging uses one piece of fluted corrugated paperboard glued between two sheets of linerboard. It is the most common type, often used to create corrugated packaging boxes.

- Double-wall: Two pieces of fluted corrugated paperboard are glued to three sheets of flat linerboard. Double-wall corrugated packaging is more durable and less flexible than single-wall corrugated packaging, making it a good fit for POP displays and extra-strong packaging.

- Triple-wall: Triple-wall stacks three pieces of fluted, corrugated paperboard to four sheets of flat linerboard. It’s strong and heavy-duty, making it best for industrial applications.

The Benefits of Corrugated Packaging

Corrugated packaging has numerous benefits for businesses of all sizes. The top advantages of corrugated packaging include:

Lightweight Yet Strong

Corrugated packaging is a lightweight material that protects shipped products without adding extra weight to them. Nonetheless, the corrugated packaging layers make it very strong relative to its weight, ensuring it can withstand harsh shipping and handling conditions. It’s resistant to bumps, knocks, drops and vibrations during shipping and distribution.

Customizable

Corrugated packaging is a versatile material that you can customize for numerous uses. It can be cut into various shapes, sizes and thicknesses and folded to fit a variety of products, including large and irregularly shaped items. You can also customize corrugated packaging with different paper types, adhesives and flute sizes.

To help your business stand out and increase brand awareness, you can personalize the exterior of your corrugated packaging. You can print or stick packaging labels relaying company information, logos, graphics and marketing messages on the boxes.

Protective

The multilayered structure of corrugated packaging protects your products, ensuring they arrive to clients in perfect condition. The fluting adds to the packaging’s strength and cushioning properties. It protects against shocks and drops during shipping. It also shields products from moisture, dirt, dust and other elements that could tamper with the quality of the product.

Additionally, you can coat corrugated packaging with flame-retardant or water-resistant materials. These enhancements make it suitable for shipping flammable materials or transporting products in extreme conditions, such as high humidity and wide temperature variations.

Cost-Effective

Corrugated packaging is among the most affordable packaging materials. Its customizable nature allows you to cut each box to the exact size of the product, minimizing waste and eliminating unnecessary elements. As a result, you save on material and labor costs.

Ultimately, you reduce shipping and handling costs because the material is lightweight, and customization increases fill density. Its recyclable and reusable nature also makes it a cost-effective packaging option.

Eco-Friendly and Sustainable

Corrugated packaging is among the most sustainable materials. It contains 70%-100% organic and recycled materials without toxic or harmful chemicals. Additionally, corrugated packaging can be reused, renewed and recycled at the end of its life cycle.

In 2022, corrugated boxes had a recycling rate of over 93%. They are biodegradable, meaning they break down into small pieces that degrade naturally and safely reintegrate into the ecosystem.

Applications of Corrugated Packaging

The top applications of corrugated packaging include:

- Shipping and transportation: Corrugated packaging is used for the secondary packaging of items to protect them during handling, storage and distribution. The material is sturdy and stackable, minimizing product damage and shipping costs.

- Consumer packaging: Corrugated packaging can encase products to preserve and prolong their shelf life while promoting brand awareness. It protects the products from dust, moisture, dirt and other environmental factors.

- Display and point-of-sale packaging: Corrugated packaging can be customized or branded to create eye-catching free-standing or counter displays to promote retail sales.

- Commercial packaging: You can use corrugated packaging to manufacture custom packaging for wholesale or retail purposes to maximize warehouse and trailer space.

This versatile material can accommodate a wide variety of goods, including food and beverage products, fragile items, cosmetics, medications, electronics, clothes, office supplies and stationery.

Get Custom Corrugated Packaging From Great Northern Packaging

Corrugated packaging has several advantages that make it ideal for many businesses. Great Northern Packaging provides innovative, cost-effective and sustainable custom corrugated packaging solutions that vary in shape, design and size. Our sustainable packaging offers the following features:

- Made from renewable sources

- Allows secure product shipping and distribution

- Recyclable and reusable up to seven to 10 times

Reach out to us to discuss your packaging needs, or explore our variety of packaging products for numerous applications.